BD8400W Series Dehydrators

Max Capacity 8400 SCFD (9911L/h), Output Pressure 0 to 15 PSI (0 to 103.4 KPa) Field Adjustable, Single Pressure Outlet, with Real-Time Remote Management

PRODUCT DESCRIPTION

The BD8402W series dehydrators are used for pressurisation of broadcast antennas and transmission lines. The dehydrator removes the moisture from damp ambient air to deliver a reliable, constant, on-demand source of dry, pressurised air. The inherent reliability of the BD series design, combined with the high output capacity make these units an ideal choice for pressurisation of broadcast systems. Low pressure systems (suffix LP) are available for applications where reduced pressure is required, for example; pressurization of broadcast antenna radomes, broadcast waveguide transmission lines or broadcast STL systems. The BD8402W Series dehydrators employ a fully digital operating platform offering the most accurate readings of operating variables, either from the front panel or by a remote connection.

FEATURES / BENEFITS

- Dual, Independently Functioning Systems

- LCD display of All Operating Parameters

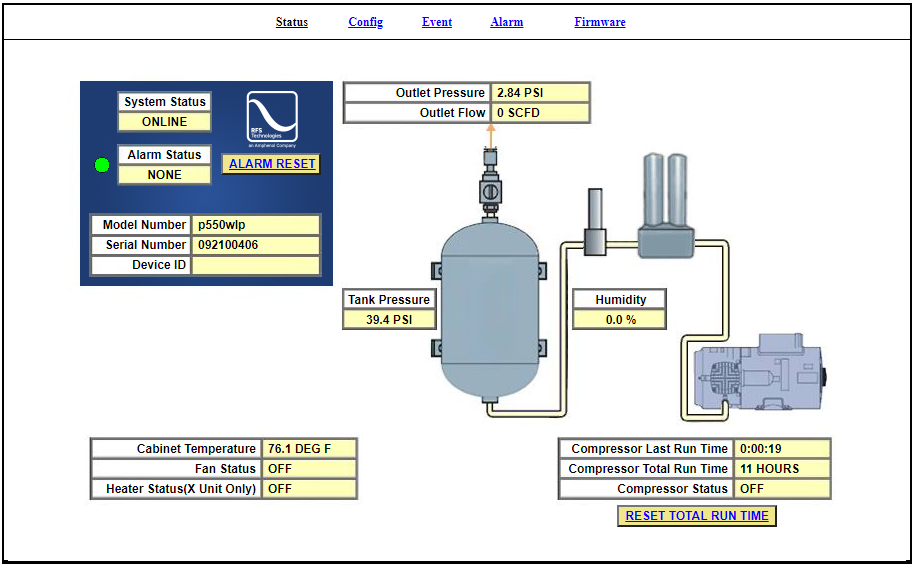

- Status & Configuration Access via Web Browser Interface

- Remote Access and Alarm Reset Capabilities

- SNMP Communication Compatible

- Accurate Humidity Sensing within ±0.1% RH

- Ultra Quiet Compressors

- Removable Compressor Tray for Ease of Maintenance

- 8,000 Hour Maintenance Interval

|

||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Note:

1. GLK-1 Kit contains fittings and valves of a single line 3/8" tubing system. It includes 1/8 NPT Gas inlet port for RF connector, Street Tee, Ball Valve, 0-15 PSI Gauge, 50' of 3/8" tube, Teflon tape and other valves, A 1/2" to 3/8" adaptor is also included for BD4200 and BD8402 series.

2. Manifold units with check valves are not recommended for pressurising antennas with dual feedlines.

Screen image showing remote display of dehydrator status and alarms

PWM4G : 4-Port Manifold with Pressure Gauges